Essential Kegerator Coupler Parts for Your Home Brew Setup

Ever wondered why your draft beer sometimes pours foamy or flat? It all comes down to the tiny yet powerful parts that link your keg and tap. Without the right setup, even the best brew can lose its crisp taste and perfect carbonation.

At Installation Parts Supply, we know that a smooth pour starts with quality hardware. No matter if you brew at home or simply enjoy draft beer, knowing these beer tap parts parts makes all the difference.

Every part—from the washers to the gas lines—matters for keeping the right pressure and taste. Over 90% of dispensing issues trace back to worn or mismatched components. A little knowledge goes a long way in keeping your system running flawlessly.

Central Ideas

- Proper coupler selection ensures optimal beer flow and flavor.

- Installation Parts Supply provides reliable plumbing solutions for draft systems.

- Regular maintenance prevents common pouring problems.

- Various brews call for particular coupler designs.

- Most system failures originate from coupler-related issues.

Define the Kegerator Coupler

A flawless draft begins with the proper keg-to-tap link. Think of the keg coupler as the connector between your CO₂ cylinder or nitrogen tank and the beer line, employing pressurized gas to deliver beer flawlessly to your taps. Consider it the powerhouse of your draft beer system—remove it, and the flow stops.

This small device has two jobs: it delivers gas to pressurize the keg and controls beer output. Within its housing is a probe, a check valve, plus dedicated gas and liquid ports. Each part ensures your brew stays carbonated and pours without foam.

| Component | Function | Frequent Problems |

|---|---|---|

| Probe | Punctures the keg seal | Misalignment causes leaks |

| Check Valve | Prevents backflow | Worn valves lead to flat beer |

| Gas/Liquid Ports | Connects to lines | Foaming from loose connections |

Misconnecting the coupler is a common error—three out of four novices slip up. End results include overflow foam, drips, or wasted brew. Check Installation Parts Supply’s charts and videos for correct setup.

Even “universal” styles need to correspond with your keg’s standards. The incorrect coupler not only spoils the beer, it can wreck your setup.

Keg Coupler Varieties and Applications

Kegs come in many styles and each needs its matching coupler. The correct coupler preserves carbonation and taste. Use these tips to select your coupler.

Standard D System Coupler

Most North American brews—about 85%—use this style. That valve locks onto domestic kegs with ease. Pro tip: Look for the Sankey name stamped on the side.

U-Type Coupler

The harp emblem identifies it for nitrogen blends like Guinness. Nitro beers rely on its special gas ratio for a silky head. A U coupler will not seat on a D-type keg—don’t attempt it.

S System (European Sankey) Coupler

Heineken and other European imports need this reverse-thread version. The left-hand twist prevents mix-ups with D Systems. Fun fact: It’s slightly taller than its American cousin.

A-, G-, and M-Type Couplers

UK/German imports call for these unique couplers:

- A System: Slides onto Warsteiner or Paulaner kegs. That slider lock never slips.

- G System: Tri-flat stem locks onto Bass & Boddingtons. Found in pubs throughout Britain.

- M-Type Coupler: Secures Schneider Weisse barrels. You’ll hear a click once it’s set.

Installation Parts Supply’s chart uses green=D, black=U, blue=S. One Midwestern brewery cut costs by $3K annually with the right couplers. Remember: True compatibility beats “universal” claims every time.

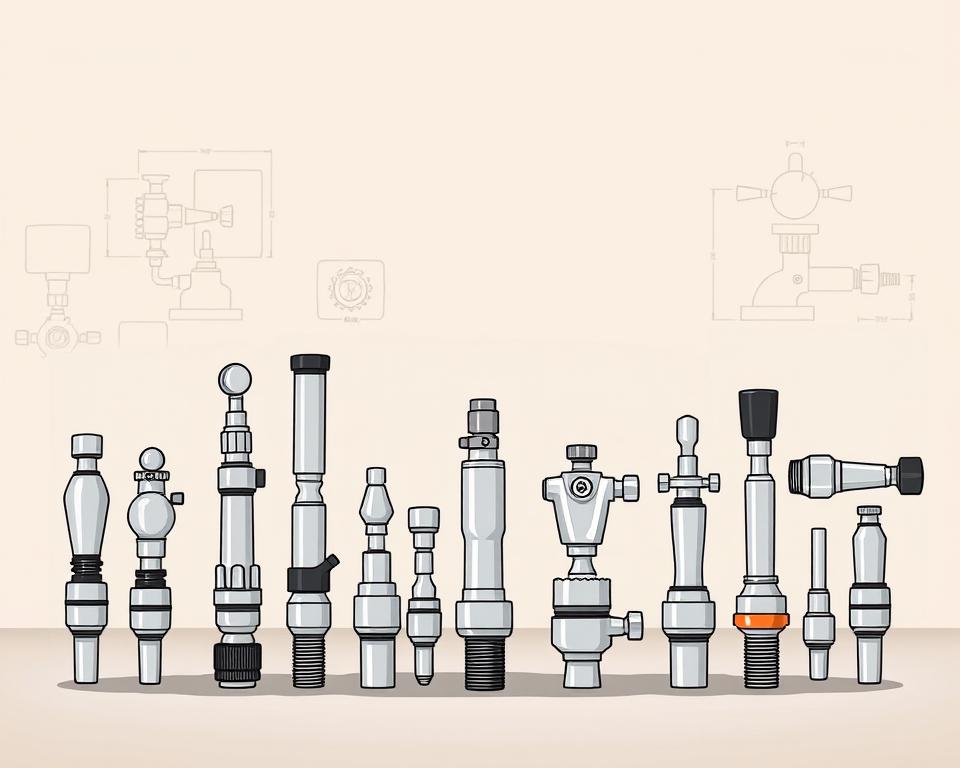

Essential Kegerator Coupler Parts and Their Functions

That perfect pour depends on finely tuned parts. Together, they keep carbonation in and foam out. Here’s a look at the parts that matter most.

Coupler Probe & Check Valve

The metal probe opens the keg’s seal for dispensing. Quality probes endure three times as many uses. Below it, the check valve blocks backflow—Installation Parts Supply’s most-replaced part.

Hex Nut and Washers

Your seal depends on that hex nut. Brass is economical; stainless fights rust. Use nitrile washers in the cold—EPDM fails below 40°F.

| Part | Material | Key Benefit |

|---|---|---|

| Probe | Stainless Steel | Resists wear |

| Check Valve | FDA-approved plastic | Stops foam issues |

| Coupler Nut | Brass/Stainless | Cost-effective & durable |

Gas and Liquid Ports

Your gas port should see 20–30 PSI pressure. Wrong PSI leads to foam. Stick to 3/16″ ID beer lines for smooth pours. Keep a rebuild kit on hand for quick fixes.

Pro Tip: Replace O-rings biannually or after ~50 kegs. A cheap washer swap saves you from a costly rebuild.

Setting Up Your Coupler

Getting your draft system right means perfect pours every time. Correct hookups avoid pouring issues. Here’s how to hook it up without hiccups.

Connecting the Coupler to the Keg

Raise the lever, line up the lugs with slots. Rotate until secure but don’t overtighten. Choose low-profile to gain 4–5″ clearance.

Installation Parts Supply’s torque wrench ensures hex nuts are secured at 8–10 ft-lbs. Eighty percent of leaks stem from a crooked probe. Always use fresh washers to maintain pressure.

Hooking Up Your Gas & Beer Lines

Hook the gas line on with 5/16″ fittings. Apply thread sealant to prevent CO₂ leaks. For beer lines, 10–12 feet of 3/16″ tubing balances pressure drop.

| Step | Tool | Note |

|---|---|---|

| CO₂ Line | Pipe dope | Test at 30 PSI for bubbles |

| Draft Line | Tubing cutter | Keep ends square for seals |

| Pressure Test | Soapy water | Check for 24 hours |

Modern rigs offer app-based pressure feedback. Our quick-connects helped a Denver bar slash foam by forty percent. Stop the CO₂ at the source for serious leaks.

Common Coupler Problems & Fixes

Foamy eruptions are the quickest way to waste beer. Once you know what to check, most issues are easy to fix. Let’s tackle the frequent headaches and their solutions.

Leaks and Foamy Beer

Foam accounts for 68% of draft system complaints. Start by checking your temperature—ideally 38°F for most ales. Too warm, and CO₂ escapes too fast.

Then, look over your draft tubing fittings. A soapy water solution reveals gas leaks through bubbles. Snug fittings carefully; overtightening can harm seals.

- Check ball may hiss and interrupt flow

- Pressure imbalance? Compare your gauge to this chart:

| Style | CO₂ Pressure | N₂ Ratio |

|---|---|---|

| Pilsners | 10–12 | N/A |

| Stouts | 25–30 | 75% nitrogen |

Loose Coupler Issues

Loose couplers almost always trace back to worn seals. Replacing seals corrects about 40% of these problems. Bent coupler heads sometimes require new units.

Shims can stabilize wobbly connections. They’re a cheap way to stop wobble. Low-profile models solve clearance problems in compact coolers.

Pro Tip: An emergency kit with five washers fixes most sudden leaks. One Chicago pub trimmed loss by 18% with staff training.

Remember—frost on your CO₂ tank signals overuse. Allow the tank to warm up prior to any valve tweaks. Digital gauges need yearly calibration for accuracy.

Maintenance for Your Coupler

Hygienic systems yield the best flavor. Leftover yeast and oils harm both taste and pouring. A simple routine keeps everything running smoothly.

Taking Apart & Soaking

First, disassemble the coupler. Separate the handle, probe, and check valve. Soak all parts in warm water with 1 oz of PBW per gallon for 15–20 minutes. It dissolves yeast and hop deposits.

Use our brush kit to clean narrow passages. Focus on the ball valve—gunk loves to hide there. Rinse fully so no cleaner remains.

Cleaning Products

Powdered Brewery Wash excels at safe cleaning. Acids clean quick but may degrade seals. Ultrasonic cleaners remove buildup in pro bars.

- Air Drying: Use compressed air or microfiber cloths.

- Sanitizing: Meet FDA CFR 117: 30 seconds to sanitize.

- Logs: Track cleanings with a template.

Ultraviolet systems help sterilize parts. Dispose of alkaline wash properly to protect drains. A little effort ensures quality pours and extends your system’s life.

Final Thoughts

Achieve brewery-quality pours with expert hardware know-how. Correct parts, clean routine, and proper install equals perfect pints. Installation Parts Supply offers lifetime support and seasonal discounts on rebuild kits to keep your pours perfect.

Regular upkeep can stretch your hardware lifespan by seven years. Download their free compatibility checklist or join a brewmaster webinar for pro tips. One yearly inspection prevents headaches—our long-term customers agree.

Upgrade now—stop by Installation Parts Supply and boost your home setup.